LEI never gives up. That’s the very reason we have made “Scrap into Shining Star” existing CO2 LASER Machine were once Customer’s necessity and now due to technological developments it has tuned to scrap.

Why to replace your old machine? Reuse with Latest Technology, Higher the performance”.

We have a Solution for upgrading your OEM machines like AMADA, LVD, JFY, TANAKA, NTC with FANUC control from CO2 into FIBER LASER machine. Also, we can upgrade any machine from Lower Power into Higher Power LASER source, LASER head, adding options like N2 gas control function etc.

Things to be noted: –

- You Know it right? All the advantages of FIBER LASER. So, we will explain the unique advantage of our retrofitting.

- Existing operations and software will be continued usage. Saving time and money for operator, software, and training.

- Machine controller, wiring, all the safety functions, Special application related options, facilities developed OEM will remain undisturbed. First & foremost, we are adding FIBER source and its additional functions.

- Mechanism very rigid and accuracy of 0.01mm. Whereas all other Chinese machine accuracy is 0.05mm

- Patented technologies like UI, Shuttle exchange, cutting technology features are inbuilt.

- Corner override function which makes perfect for sharp edges like Gear cutting application

- Fiber can cut copper, brass, and aluminium much better and more safely than CO2 because the beam is more readily absorbed and not reflected.

- Fiber laser operating costs are typically half of what a CO2 system can offer due to the lower electrical consumption and high electrical efficiency of fiber lasers. Other factors that favor fiber lasers include the absence of mirrors or beam path bellows that are necessary in CO2 systems

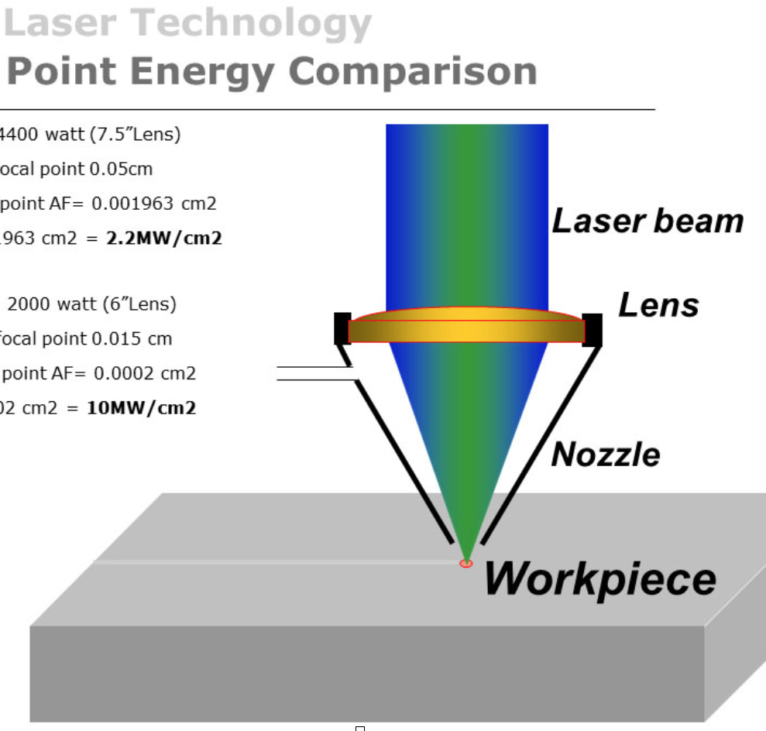

The absorption rate is influenced by the wavelength of the laser and also the angle of incidence. Higher absorption of the fiber wavelength and the higher power density created by the focused beam combine to achieve a 300 percent increase in cutting speed in thin materials that are less than 6mm thickness. Systems can certainly cut thicker and faster with higher fiber laser power, but the “sweet spot” where the most valuable benefits are realized remains in the 6mm and under range when making comparisons with CO2 systems.

Different types of lasers have different wavelengths, for examples the fibre (SSL) laser’s wavelength is far smaller at 1 micron (on the right ) than the C02 lasers wavelength t 10 micron , shown in left.

The angle of incidence means, the distance between point at which the laser beam hits the material (or surface), perpendicular (at 90) to the surface, so where it makes a T shape.The angle of incidence increases (shown as a1 and a2 below) as the material increases in thickness. You can see below that with the thicker material, the orange line is at a greater angle than the blue line on the diagram below.

The angle of incidence means, the distance between point at which the laser beam hits the material (or surface), perpendicular (at 90) to the surface, so where it makes a T shape.The angle of incidence increases (shown as a1 and a2 below) as the material increases in thickness. You can see below that with the thicker material, the orange line is at a greater angle than the blue line on the diagram below.

Which laser type for which application?

Fiber Laser/SSL Highlights

- Speed – Faster than CO2 lasers in thin materials as the laser can be absorbed quickly with a slight lead in speed when cutting with Nitrogen (fusion cutting).

- Cost per part – less than the CO2 laser depending on sheet thickness.

- Safety – Strict safety precautions must be taken (machine is completely enclosed) as the laser light (1µm) can pass through very narrow openings in the machine’s frame causing irreparable damage to the eye’s retina.

- Beam guidance – fiber optics.

Modal Box Title

- Quality – Quality is consistent throughout all thicknesses of material.

- Flexibility – high, suitable for all material thicknesses.

- Safety – CO2 laser light (10µm) is better absorbed by the machine frame, which lowers the risk of irreparable damage to the retina. Personnel should not look directly at the cutting process through the acrylic pane in the door as the bright plasma also presents a risk to sight over a period of time. (Similar to looking at the sun.)

- Beam guidance – mirror optics.

- Cutting with Oxygen (flame cutting) – there is no difference in quality or speed shown between the two types of lasers.

Much More to explain… Visit us to discuss more interesting feature…